Characteristics:

In order to achieve its maximum molding productivities, simply using its ultra micro breathing cell to exhale gas and air from molds.

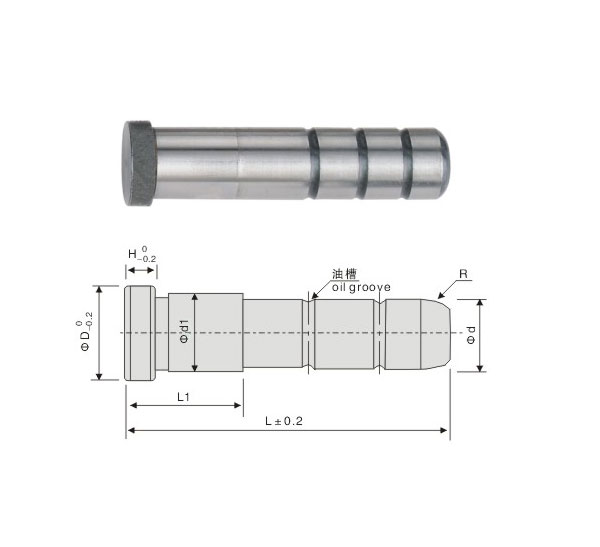

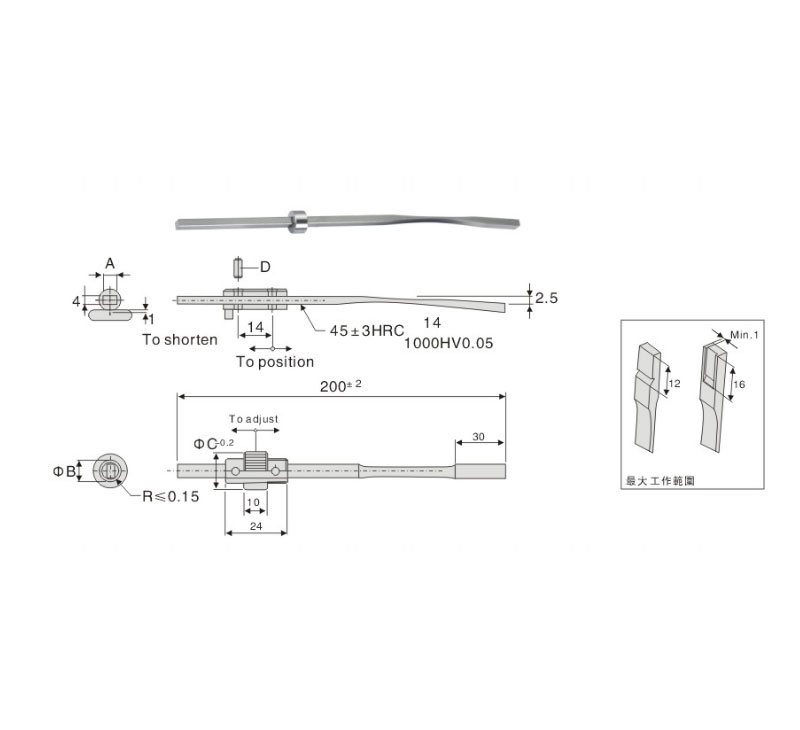

Stainless steel: special for ejection mold Hardness: RV50 pore diameter: 0.03

Copper: special for vacuumed mold Hardness: RV20 pore diameter: 0.5

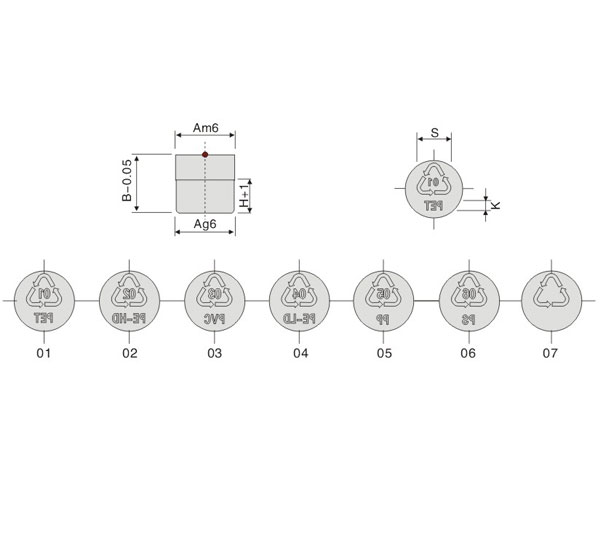

| Catalog No. | L | |

| Type | D | |

| JH077 | 4 | 4.5 |

| 5 | 10 | |

| 6 | 10 | |

| 8 | 10 | |

| 10 | 10 | |

| 12 | 12 | |

• Order: Catalog No. D X L

Common Questions:

1. Burnt

When aberration and burnt issues occurred, it is because resin is filling faster than air exhaling which will result gasvent to overheat.

2. Overflow:

There are 2 possible conditions:

– When temperature of resin gets higher at the tip of seaming, it weakens its bonding strength.

– Air can filled up the path and blocks resin to flow functionally which will cause ejection pressure to rise and materials to overflow.

3. Not enough fillings:

Due to air pressure, it reduces the ratio of the flling speed. Even there is no any sign of burnt or overflow.

4. Cell Streak:

If there are some cells, streaks and mottles occurred, it is because the cells have not been vaporized completely between air and resin.

5. Extensive Cycling Time:

The higher temperature of resin, molds and slower speed of injection cause extensive cycling time, however, it will not affect the

quality of final products.

Energy, Time, and Cost Saver:

1. It will reduce the trial die, time and materials if users consider to use TX gasvent the beginning of the design.

2. It will save up to 1/3 to 1/10 of the total cost and time if installing Sintered Vents.

Installation:

1. Do not touch the surface when Gas Vents is in use.

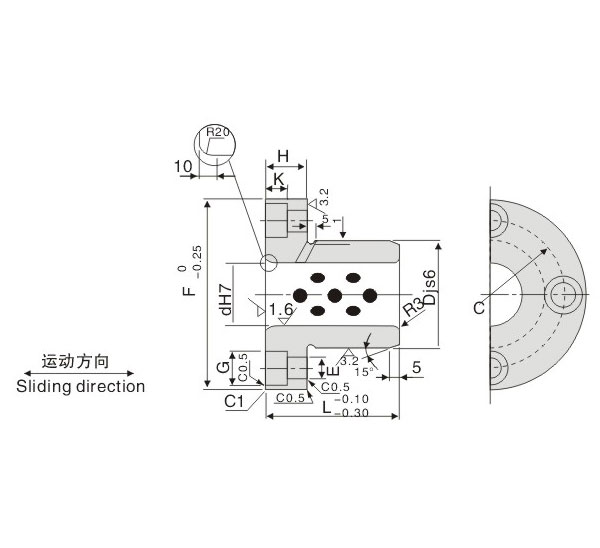

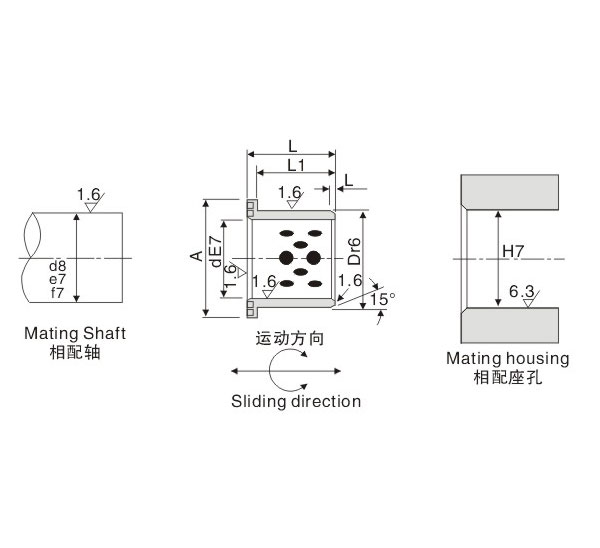

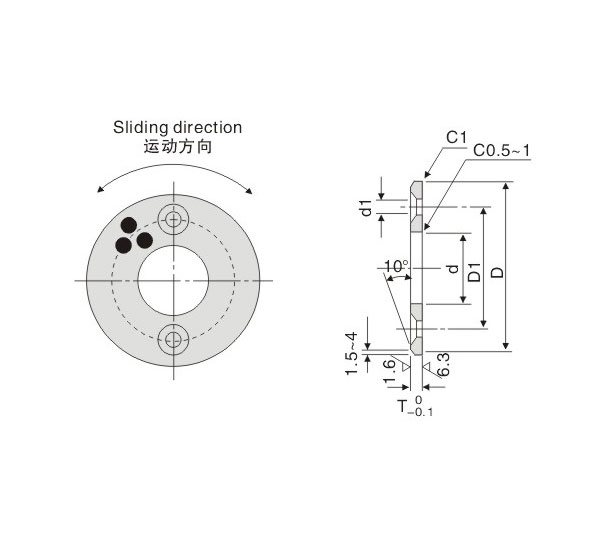

2. Use H7/S6 from JIS reference chart.

English

English Le français

Le français España

España lingua italiana

lingua italiana