DGS series-Damped Gas Springs

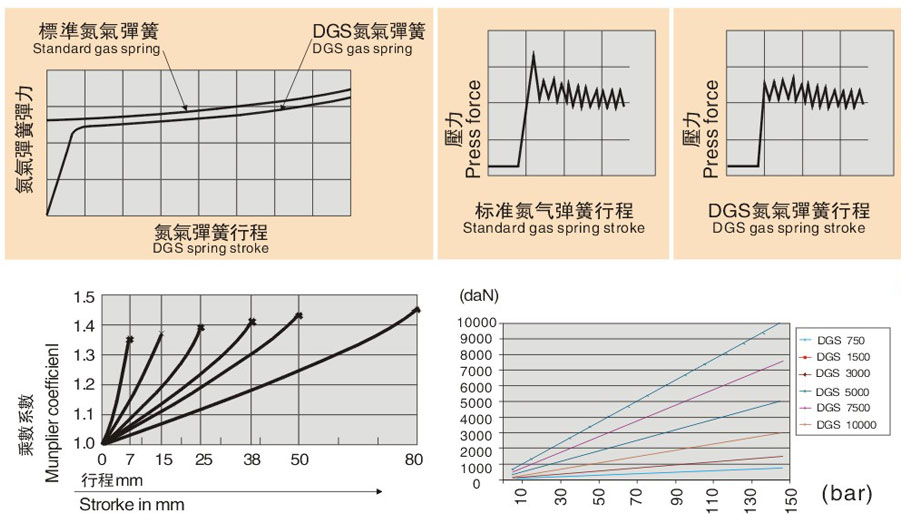

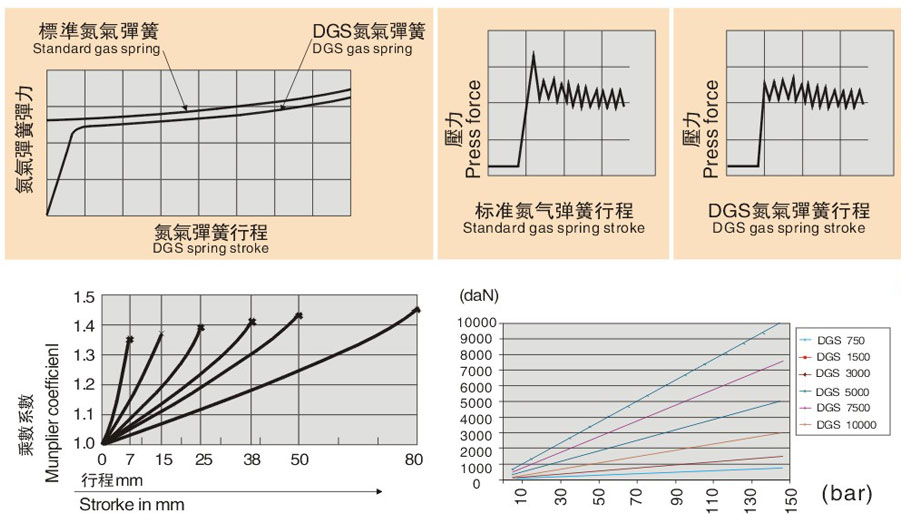

• Progressive increase of pressure and constant acceleration.

• Lower impact on press cushion.

• Reduce maintenance costs and improving production.

• Keep all dimensions forces and fastening from the ISO series.

| Model |

Force(da N) |

Body(mm) |

Repairable |

Connectable |

Filling Port |

| DGS-750 |

750 |

50 |

YES |

YES |

1/8" Gas |

| DGS-1500 |

1500 |

75 |

YES |

YES |

1/8" Gas |

| DGS-3000 |

3000 |

95 |

YES |

YES |

1/8" Gas |

| DGS-5000 |

5000 |

120 |

YES |

YES |

1/8" Gas |

| DGS-7500 |

7500 |

150 |

YES |

YES |

1/8" Gas |

| DGS-10000 |

10000 |

195 |

YES |

YES |

1/8" Gas |

| Pressure medium |

N2 |

| Max.charging pressure |

150bar |

| Min.charging pressure |

20bar |

| Operating temperature |

0°~100° |

| Max.Piston rod speed |

1.6m/s |

| Refillable |

Yes |

| Connectable |

Yes |

| Re: A 10% stroke length allowance is recommended. |

| Special Nitrogen Gas Spring out of catalogue are manufactured under order. |

Technical Features

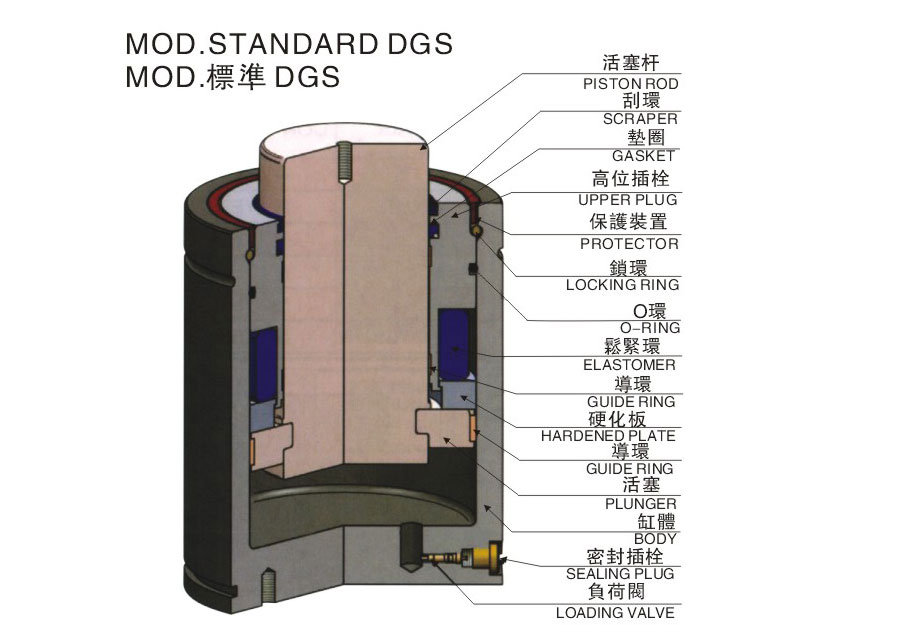

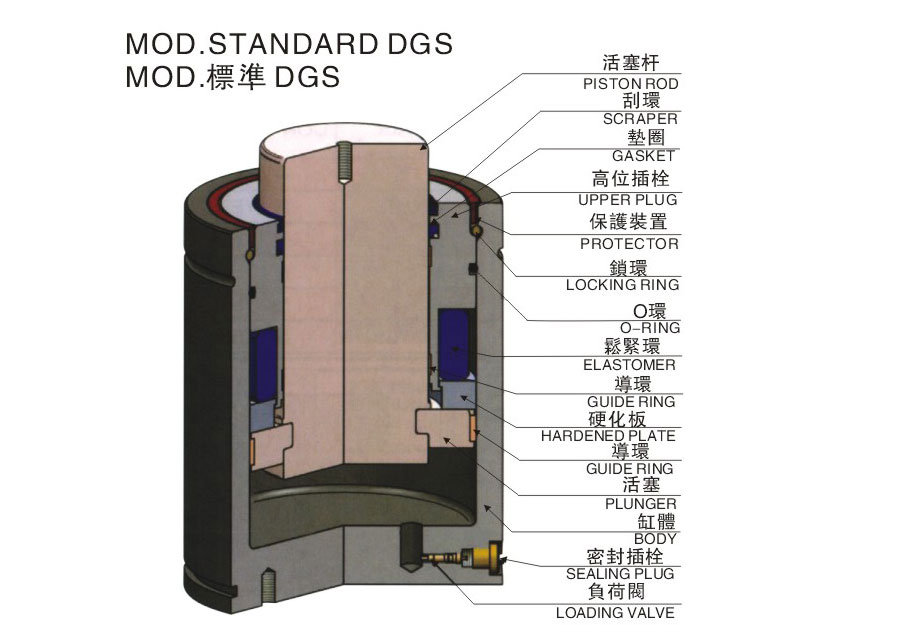

- DGS Nitrogen Gas Spring are specially designed to enjoy a longer life expectancy by reducing maintenance tasks that makes easier for the tool and press stamping facilities to face the most common challenges higher production in an more efficient, healthier and safer working environment thanks to the lower noise levels achieved. From the standard Nitrogen Gas Spring, improvements have been in troduces.

|

- Low force increase for the gas spring at the beginning of the stroke let a smooth and uniform acceleration that allows less wearing of guiding and sealing elements. Inaddition, it involves lower press efforts when start moving each Nitrogen Spring rod and reduce wear on both press and tool. All these considerations save timing and maintenance costs.

|

- Damped effect for the Nitrogen Gas Spring plunger against the upper plug, makes considerable quieter the sound level produced in each stroke. Contributing to a healthier and safer working environment.

|

- Vibrations transmitted by the gas spring are lower. This in turn, let improve production conditions by making easier quality part transfer and more uniform pad operation.

|

English

English Le français

Le français España

España lingua italiana

lingua italiana